Hello Everyone,

So Dr. Moller and crew have been working really hard to clean up the site, and the results are pretty dang awesome. You have seen the updated photos of the wind tunnel already. Well I have a bunch of new photos to share with you showing all the work that has been done (some folks requested additional pics).

Here is a pic of our hybrid car (70 MPG!) and the Sea Rayder that has a dual-rotor 530cc engine (we rev up the boat engine for visitors – it’s bone jarring!). The boat was cleaned up and brought here into our FM front office space.

On the other side of the room we put the Aerobots and other misc. inventions that Dr Moller has built over the years.

On the other side of the room we put the Aerobots and other misc. inventions that Dr Moller has built over the years.

The Skycar M200 and the Skycar 100 prototypes, along with the Rotapower scooters are still in the same place.

The Skycar M200 and the Skycar 100 prototypes, along with the Rotapower scooters are still in the same place.

They moved all the sample engine components onto a single presentation table, but ordered them by the various engine sizes. Left side is the 27cc engine, with the weed wacker prototype. Next is the 150cc, then the 530cc parts in two rows in the middle with the Skycar engine behind the first row. Rightmost are the 650cc industrial engine components and two assembled engines (a single-rotor and a dual-rotor).

They moved all the sample engine components onto a single presentation table, but ordered them by the various engine sizes. Left side is the 27cc engine, with the weed wacker prototype. Next is the 150cc, then the 530cc parts in two rows in the middle with the Skycar engine behind the first row. Rightmost are the 650cc industrial engine components and two assembled engines (a single-rotor and a dual-rotor).

Here is a pic of the back room, our lab space. In front is one of the Neuera Firefly monocoque airframes sitting in the fiberglass mold. Behind that you can see the Neuera and the Skycar M400, and of course the wind tunnel in the background.

Here is a pic of the back room, our lab space. In front is one of the Neuera Firefly monocoque airframes sitting in the fiberglass mold. Behind that you can see the Neuera and the Skycar M400, and of course the wind tunnel in the background.

Here is a closer pic of the wind tunnel in place.

Here is a closer pic of the wind tunnel in place.

This is another back room where we have some of the refurbished machine shop tools (we still have a LOT in storage, including our CNC machines.)

This is another back room where we have some of the refurbished machine shop tools (we still have a LOT in storage, including our CNC machines.)

Here is another pic of the our main lab space from another angle.

Here is another pic of the our main lab space from another angle.

Here is a pic of our biogas test stand – siding was added and it was painted to make it look nicer.

Here is a pic of our biogas test stand – siding was added and it was painted to make it look nicer.

Another pic of the biogas test stand, from the opposite side.

Another pic of the biogas test stand, from the opposite side.

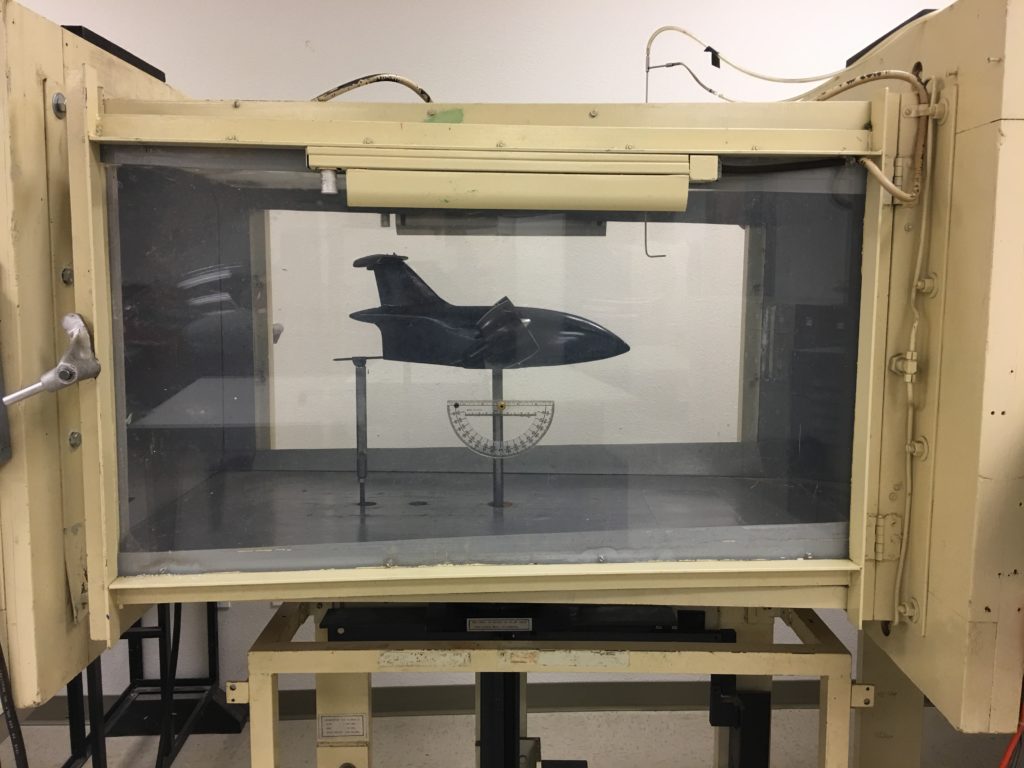

The “pièce de résistance”, Dr Moller’s new Skycar 100 model for the wind tunnel. He’s been working on it for a few weeks. It was build to test lift/drag effects of the ducted fans on the model.

The “pièce de résistance”, Dr Moller’s new Skycar 100 model for the wind tunnel. He’s been working on it for a few weeks. It was build to test lift/drag effects of the ducted fans on the model.

Here is another pic of the model in the wind tunnel test section.

Here is another pic of the model in the wind tunnel test section.

That’s pretty much all the pics I have to share.

That’s pretty much all the pics I have to share.

Oh, and a bit of news! We may have just sold our first engine for a biogas generation system. I will provide more details next week once we finalize the deal, but this will be a joint research project to run our engine in the field on anaerobic digester biogas. We will share data, knowledge and all learnings between FM and the other company. We will be paid for the engine and we will provide support for site installation, engine tuning and operation. The other company will supply the generator, inverter, system enclosure and remote monitoring capability. If our engine works as expected, this will open up an opportunity to many other biogas generation projects with this company in the near future.

Best Regards – Dave